System-level

Tools: MEMS Xplorer combined with Cadence provides system-level design capability through

fully hierarchical schematic capture and behavioral level simulation of

MEMS devices with electronics and packaging. MEMS devices are

represented with multi-physics signals in mechanical, thermal,

magnetic, fluidic, optical, and electro-static domains in Verilog-A. The MEMS

Verilog-A library

contains models for popular MEMS devices. Simulation modes

include AC, DC operating point, DC transfer sweep, Fourier, Noise,

Transient, Transfer function, and Parametric Sweep.

MEMS Master is

a position dependant schematic tool for rapidly creating hierarchical

MEMS models from primitive devices. Models from

MEMS Master can then be simulated in the Cadence analog/mixed signal

simulator environment ensuring the link with system designers.

Modeling: MEMS

Modeler automatically

generates coupled electro-static-mechanical- thermal behavioral models

ready for system simulation with electronics and packaging from 3D data

from analysis packages. Complex, finite element models involving a

large number of degrees of freedom are reduced to a few master degrees

of freedom. Users can also create their own models from analytical

equations and the tool generates simulation-ready descriptions in

Verilog-A.

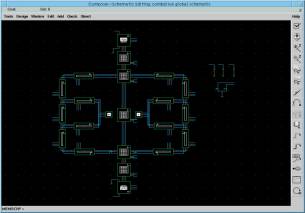

Layout

Editing: MEMS

Xplorer enhances Virtuoso capabilities for MEMS mask design. Easy

MEMS offers automatic generation of curved shapes such as torii, splines, fillets, and general equation-based curves. MEMS Device Generators speed

up the development of complex mask geometries by enabling designers to

create process-compatible, parameterized, often-used blocks that may be

combined to construct larger designs. A

library of often used MEMS structures included. The Easy

MEMS tool helps to automate tasks that are time-consuming for creating MEMS

mask layout such as creating polar arrays and useful macros include the

generation of holes and dimples to properly release MEMS structures.

The MEMS

Etching Emulator allows

a 2D analysis of how the design will appear after anisotropic bulk

etching.

MEMS Xplorer has

an intuitive user interface and provides MEMS-specific capabilities

that greatly reduce mask layout time. Popular output formats are

supported so mask designs are “foundry ready”. MEMS

Verification provides

a configurable design rule checker that verifies MEMS layout against

fabrication requirements to prevent costly design errors causing extra

fabrication runs and ensures manufacturability.